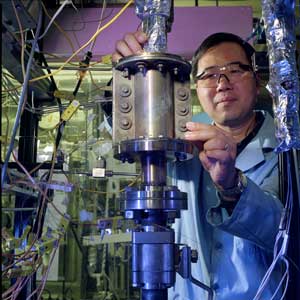

Dr. Di-Jia “D. J.” Liu

The PhysOrg article Practical on-board hydrogen storage is goal of new Argonne research project said

“Solving one of the biggest problems in commercialization of fuel-cell-powered automobiles is the goal of a new $1.88 million research project on on-board hydrogen storage at the U.S. Department of Energy’s Argonne National Laboratory.To be practical, researchers say, the hydrogen storage system must be able to hold enough of the fuel for a driving range of 300 miles before refilling; no current technology meets this goal within the constraints of allowable weight and volume for passenger cars.

The Argonne research will investigate nanostructured polymeric materials as hydrogen storage adsorbents. Developed through an earlier collaboration between Argonne and the University of Chicago, the new polymer adsorbent material has shown great promise in preliminary tests. The new project funded by DOE will seek further improvements in storage capacity and an in-depth understanding of hydrogen-polymer interactions.

‘The successful outcome of the project will lead to a low-cost, high-capacity hydrogen storage material that can be mass-produced within the existing industrial infrastructure,’ said Di-Jia Liu, Argonne scientist who is leading the research project.”

Di-Jia “D. J.” Liu, Ph.D. is Chemist and Principal Investigator in the Catalysis and Energy Conversion group of the Chemical Sciences and Engineering Division, Argonne National Laboratory. He studies hydrogen storage for transportation purposes; fuel cells; and batteries, including Li-Air batteries, which may be the next generation of lithium batteries.

Specific research activities include leading teams in synthesis and characterization of nanostructured polymeric materials for on-board hydrogen storage application; preparing aligned carbon nanotube based membrane electrode for proton exchange membrane (PEM) fuel cell application; low-cost electrode catalysts as alternative to platinum group metals for fuel cell; studying catalytic transition state via ultrafast X-ray spectroscopy; CO2 conversion and mitigation through green chemistry; and next generation materials for Li-Air battery.

His achievements include:

- Development of nanostructured carbons as new materials for membrane electrode and Pt-free electrocatalyst in PEM fuel cell application

- Development of nanostructured polymer and carbon composite as on-board hydrogen storage material for transportation application

- Development of new catalyst and support materials for direct alcohol fuel cell application

- Investigation of solid oxide fuel cell material using microfocused synchrotron X-ray scattering technique

- Development of diesel reforming catalyst and reactor for production of hydrogen rich reformate in fuel cell and emission post-treatment application

- Development of electrochemical CO removal technology for PEM fuel cell application

- Development of a state-of-the-art ozone catalytic converter for Boeing 777 aircraft environmental control system

- Development of NOx reduction catalyst system for lean-burn automotive combustion engine emission control

- Development of catalytic coating for CO and VOC remediation for microturbine power generator

- Development of in-situ and real-time synchrotron X-ray absorption spectroscopic method for catalyst characterization under the reaction condition

- Six-Sigma Black Belt for industrial process development through statistical design and control principles

His papers include The v3 Fundamental Band of HCNH+ and the 2v3 ← v3 and v2 + v3 ← v2 Hot Bands of HCO+, Crossed-beam studies of radical reaction dynamics: CN + O2 + NCO (X2Π) + O, In situ XANES characterization of the Cu oxidation state in Cu-ZSM-5 during NO decomposition catalysis, Characterization of kilowatt-scale autothermal reformer for production of hydrogen from heavy hydrocarbons, and Rotational spectroscopy of molecular ions using diode lasers.

His patents include Autothermal reforming catalyst having perovskite structure, Environmental control system including ozone-destroying catalytic converter having anodized and washcoat layers, Tubular catalytic aircraft precooler, Catalytic adsorption and oxidation based carbon monoxide sensor and detection method, Emissions control in a recuperated gas turbine engine, and Electro-catalytic oxidation (ECO) device to remove CO from reformate for fuel cell application.

D. J. earned his BS in Chemistry at Beijing University in 1982, his Ph.D. in Physical Chemistry at The University of Chicago in 1987, and did his Postdoc work at The University of California at Berkeley.