A new method is described that uses a periscope to generate high-speed, high-resolution projections of light fields, enabling sub-second volumetric 3D printing of millimetre-scale objects without rotating the sample.

Additive manufacturing (AM) methods, such as 3D printing, enable the realization of objects with different geometric properties, by adding materials layer-by-layer to physically replicate a digital model. These methods are now widely used to rapidly create product prototypes, as well as components for vehicles, consumer goods and medical technologies.

A particularly effective AM technique, called direct ink writing (DIW), entails the 3D printing of objects at room temperature using inks with various formulations. Most of these inks are based on fossil-derived polymers, materials that are neither recyclable nor biodegradable. Recently introduced lignin-derived inks could be a more sustainable alternative. However, they typically need to be treated at high heat or undergo permanent chemical bonding processes to reliably support 3D printing. This prevents them from being re-utilized after objects are printed, limiting their sustainability.

What happens to soft matter when gravity disappears? To answer this, UvA physicists launched a fluid dynamics experiment on a sounding rocket. The suborbital rocket reached an altitude of 267 km before falling back to Earth, providing six minutes of weightlessness.

In these six minutes, the researchers 3D-printed large droplets of a soft material similar to the inks used for bioprinting —a developing technology that shows huge potential for regenerative and personalized medicine, tissue engineering and cosmetics. Bioprinting involves 3D-printing a mix of cells and bio-inks or bio-materials in a desired shape, often to construct living tissues.

The experiment was called COLORS (COmplex fluids in LOw gravity: directly observing Residual Stresses). Using a special optical set-up, the researchers could see where the printed material experienced internal stresses (forces) as the droplets spread and merged. Stressed regions stand out as bright colors in the experiment. Investigating how and where these stresses emerge is important because they can get frozen in a material as it solidifies, creating weak points where 3D-printed objects are most likely to break.

The human kidney filters about a cup of blood every minute, removing waste, excess fluid, and toxins from it, while also regulating blood pressure, balancing important electrolytes, activating Vitamin D, and helping the body produce red blood cells. This broad range of functions is achieved in part via the kidney’s complex organization. In its outer region, more than a million microscopic units, known as nephrons, filter blood, reabsorb necessary nutrients, and secrete waste in the form of urine.

To direct urine produced by this enormous number of blood-filtering units to a single ureter, the kidney establishes a highly branched three-dimensional, tree-like system of “collecting ducts” during its development. In addition to directing urine flow to the ureter and ultimately out of the kidney, collecting ducts reabsorb water that the body needs to retain, and maintain, the body’s balance of salts and acidity at healthy levels.

Finding ways to recreate this system of collecting ducts is the focus of researchers and bioengineers who are interested in understanding how duct defects cause certain kidney diseases, underdeveloped kidneys, or even the complete absence of a kidney. Being able to fabricate the kidney’s plumbing system from the bottom up would be a giant step toward tissue replacement therapies for many patients waiting for a kidney donation: In the U.S. alone, 90,000 patients are on the kidney transplant waiting list. However, rebuilding this highly branched fluid-transporting ductal system is a formidable challenge and not possible yet.

Tungsten carbide–cobalt (WC–Co) is prized for its hardness, but that same property makes it unusually difficult to shape. The current process is wasteful and expensive for the yield produced, and an economically sensible method for creating these materials is long overdue.

WC-Co cemented carbides are important in fields that require high wear resistance and hardness, such as cutting and construction tools. Currently, these carbides are made using powder metallurgy, utilizing high pressure and sintering machines to combine the WC and Co powders to yield a manufactured cemented carbide.

Though this method does produce highly durable and hard final products, a lot of expensive material is used, and the yield is suboptimal.

Additive manufacturing has revolutionized manufacturing by enabling customized, cost-effective products with minimal waste. However, with the majority of 3D printers operating on open-loop systems, they are notoriously prone to failure. Minor changes, like adjustments to nozzle size or print speed, can lead to print errors that mechanically weaken the part under production.

Traditionally, manufacturers fix these issues on a case-by-case basis, ultimately “babysitting” the printer to manually adjust parameters and test samples in an effort to figure out what went wrong.

All three are explained in more detail in the bill, but arrive at broadly the same destination. This law, if approved, would prevent 3D printer brands from selling their wares in Washington State without stringent controls to prevent the printing of 3D firearms, or indeed parts that could be used to modify existing weapons.

According to the bill, violating this proposed law would be a class C felony, which means anyone found in violation of these terms could face up to five years in prison and a $15,000 fine.

Washington is not the first state to propose addressing 3D-printed firearms by way of legislation, and is unlikely to be the last. Earlier this month New York took steps to ban 3D-printed guns, proposing the mandating of 3D printer safeguards and cracking down on the sharing and possession of 3D files containing guns or gun components.

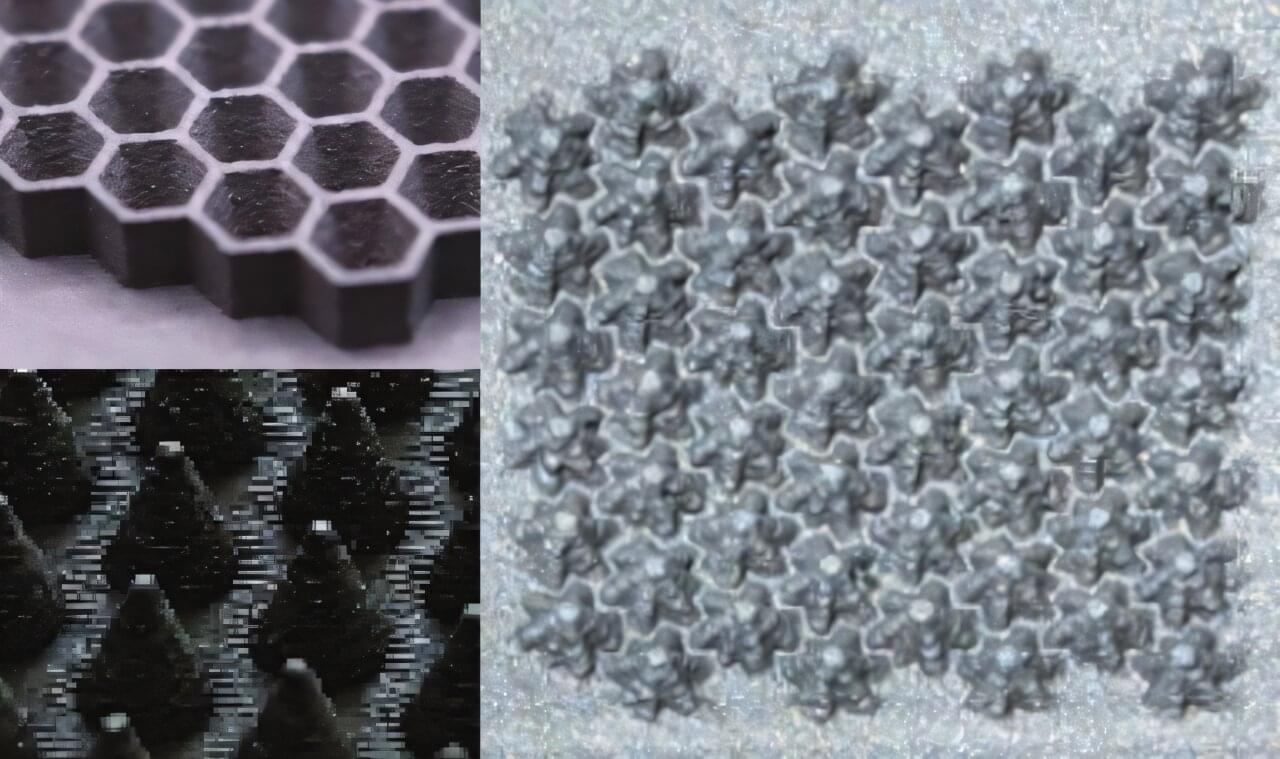

Scientists have created 3D printed surfaces featuring intricate textures that can be used to bounce unwanted gas particles away from quantum sensors, allowing useful particles like atoms to be delivered more efficiently, which could help improve measurement accuracy.

The researchers from the University of Nottingham’s School of Physics and Astronomy created intricate, fine-scale surface textures that preferentially bounce incident particles in particular directions. This can help to keep unwanted particles out of the way. The team demonstrated this by applying it to a surface-based vacuum pump and tripled the rate at which it removed nuisance gas particles.

The study, “Exploiting complex 3D-printed surface structures for portable quantum technologies,” is published in the journal Physical Review Applied.